Description

- Date: September 6, 2024

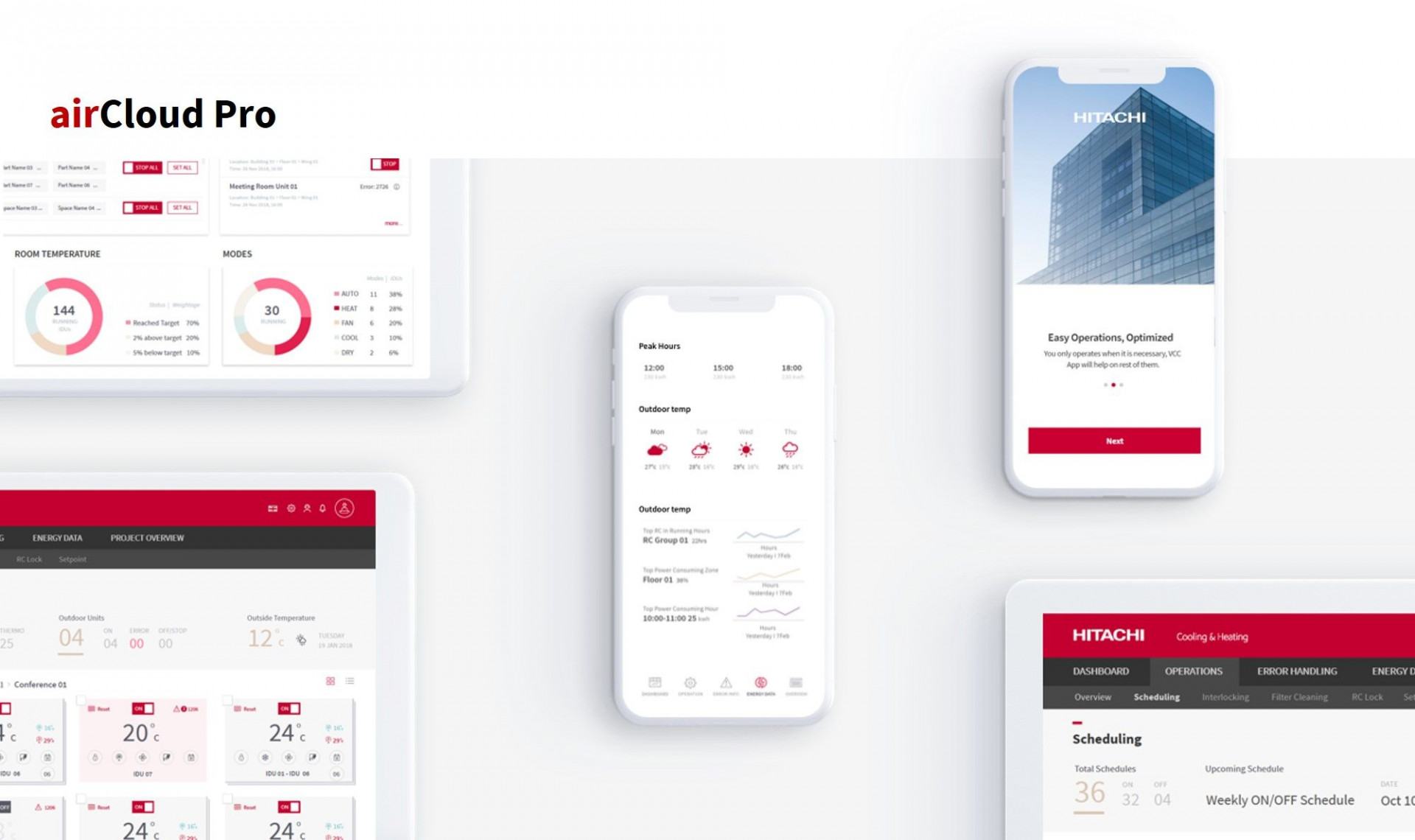

Worked on the first commercial IoT product of Johnson Control HITACHI. The system was the backbone of the IoT solution for Johnson Control HITACHI to make the HVAC systems smarter.

My Role: Tech Lead (Web & Cloud), Application Development Team

Project Overview :

The project was a significant journey in IoT development with Johnson Control HITACHI

- Originating from a proposal at Japan IT Week 2018.

- Involvement in an IoT project, requiring adaptation to new technology stacks recommended by JCH.

- Collaboration with various international JCH teams for solution development and validation.

- Overcoming strong competition to become a top contender.

- Demonstrating exceptional capability through a competitive study and a proof-of-concept using KII cloud, leading to strong recommendations.

- Ultimately being selected to take over the project due to the initial vendor’s struggles.

- Extensive international collaboration, including multiple visits and training sessions.

- Growth of the team and expansion into additional projects.

- Successful project completion and delivery to JCI Milwaukee, USA.

- The project, “Air Cloud Pro,” forms the backbone of the IoT solution for smarter HVAC systems by Johnson Control HITACHI.

Project Video: https://www.youtube.com/watch?v=JhdOm6YO6C0

Project Details: https://www.hitachiaircon.com/mea/en/ranges/iot-solutions-controllers/aircloudpro

2 years journey in 5 minutes : https://www.youtube.com/watch?v=OU1T7bHG2mE

Challenges we overcome :

- Managing Different Time Zones

- The project involved stakeholders from six different time zones, creating complexities in coordination and project management.

- The time differences led to delays in decision-making, communication bottlenecks, and scheduling inefficiencies.

- Ensuring Secure Data Flow from JCH

- A total of 80 security items needed to be addressed to ensure data flow security.

- Each item required thorough assessment and implementation of appropriate security measures.

- Scheduling

- The gateway device relied on legacy firmware for scheduling, creating challenges in managing gateway operations.

- Scheduling an IDU required generating a .dat file containing a 3,133-byte-long string for each IDU. With a maximum of 160 IDUs per gateway, the file became large, making debugging and testing difficult.

- The testing of .dat files was exclusively handled by the gateway team, leading to delays and inefficiencies.

- Over-the-Air (OTA) Updates

- Initially, the firmware could not be updated once the devices were shipped, a limitation discovered just before release.

- The hardware team introduced OTA updates at the last moment, allowing remote firmware upgrades.